Auto-Gantry Movement(Abbr. AGM)

Products

Information

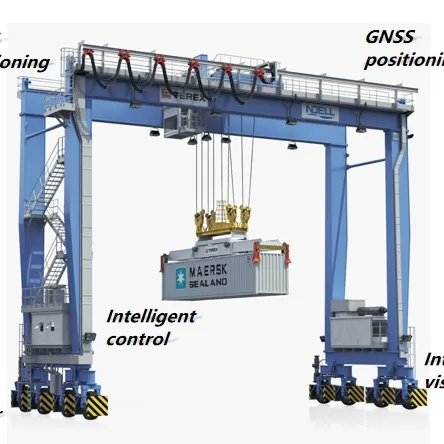

The positioning and recognition technology of satellite, laser and vision multi-mode integration realizes the automatic driving of the RTG crane, including Automatic Gantry Steering, Gantry Positioning, Intelligent Anti-collision and Precisely Parking. It can carry out efficient operation in the terminals where people and vehicles are mixed and traditional truck and AGV mixed situation.

AGM can receive TOS commands and controls the gantry to drive automatically to the pre-programmed bay and stop precisely at the target position, which efficiency is better than an experienced RTG driver.

1.Auto-gantry steering accuracy of ±30 mm while automatic driving

2.Parking deviation accuracy of ±20 mm (gantry orientation)

3.Parking deviation accuracy of ± 10 mm (trolly orientation)

4.Accuracy of obstacle detection is 99.9%, gantry safety assured

5.Up to 95% of full speed

6.Driving efficiency is higher than traditional manual operation